- 【 Breaking News 】 Chairman Liao Yongping has been honored as the third president of the Guangdong Hunan Linxiang Chamber of Commerce

- Innovation in Bonding in Luggage Production: How does Hot Melt Adhesive Reshape Durability and Production Efficiency

- A new option for fixing Electronic wiring harness terminals: How does hot melt Adhesive Ensure stable connections and efficient production

- New Trends in Shoe material Bonding: How Can Hot melt Adhesive Sticks Enhance Efficiency and empower the Shoe-making industry

- Say goodbye to slow drying and glue overflow! Manual bonding of special hot melt adhesive rods ensures fast and stable production

- Innovating the bonding process of handbags: Hot melt adhesive is a powerful tool to reshape packaging quality and efficiency

- Hot melt adhesive sticks for car dent repair: Revolutionizing traditional techniques, reshaping repair efficiency and quality

- Odorless and no drawing! Exclusive hot melt adhesive sticks for export, unlocking a new experience of efficient bonding

- How does hot melt adhesive empower cost reduction and efficiency improvement in the production of air filter elements

- New EPE pearl cotton bonding solution: Hot melt adhesive particles solve the bonding problems of multi-layer composites and special-shaped materials

With the rapid development of the global automobile manufacturing industry, the requirements for automobile manufacturing materials and their bonding methods are also increasing. As an efficient and environmentally friendly adhesive, hot melt adhesive is playing an increasingly important role in the automobile manufacturing industry. As a professional hot melt adhesive manufacturer, we are proud to be able to provide the majority of automotive manufacturers with excellent hot melt adhesive products.

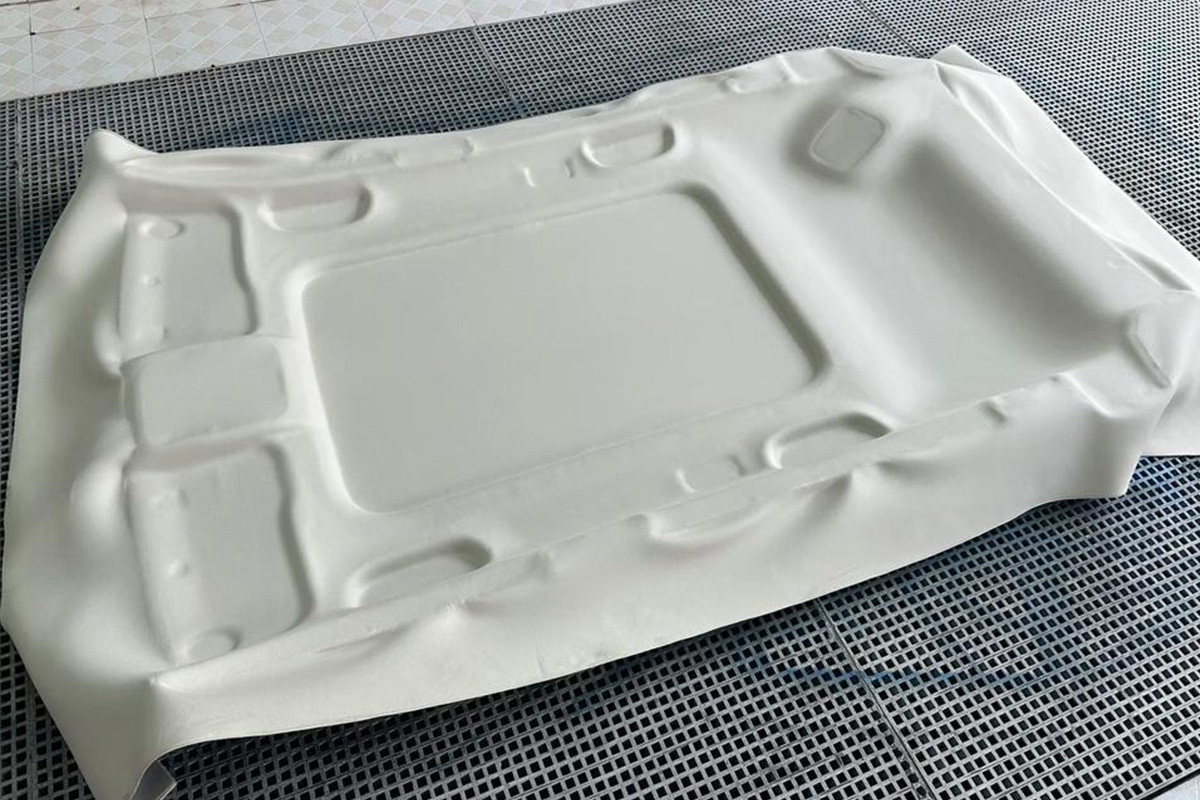

The application of hot melt adhesive in automobile bonding is very extensive, covering many key links in automobile manufacturing. In terms of ceiling bonding, hot melt adhesive can effectively bond PP, ABS, plastics, non-woven fabrics and other materials to provide solid support and beautiful appearance for the automotive ceiling. In terms of interior fixing, hot melt adhesive is widely used in the fixing of bridge instrument panel, ventilation duct, interior fixing buckle and other components, which not only improves production efficiency, but also significantly improves product quality and sealing performance.

In addition, hot melt adhesives have more specific applications in automotive manufacturing. For example, in the fixing of carpet and floor insulation MATS, hot melt adhesive plays an important role. It requires a long opening time, easy to assemble and fit large pieces, while good heat resistance, less odor, to ensure the comfort and safety of the car interior. In terms of component sound insulation sealing, hot melt adhesive is used for the sound insulation sealing of high-end automotive components, which can maintain hardness in a high temperature environment, thus ensuring the sealing and sound insulation effect of the car. In addition, hot melt adhesive is also used to fix the headlamp, compared with the traditional mechanical fixing or screw sealing method, hot melt adhesive can quickly bond and play a sealing role, reducing costs, and conducive to automated production.

The reason why hot melt adhesive can occupy an important position in the automobile manufacturing industry is mainly due to its significant advantages. First of all, hot melt adhesive has the characteristics of fast curing speed and convenient construction, which can greatly improve production efficiency. Secondly, the adhesion and flexibility of hot melt adhesive is good, and it can adapt to a variety of complex bonding needs.

Looking to the future, with the continuous development of the automobile manufacturing industry and the increasingly strict environmental protection policies, the application of hot melt adhesives in automotive bonding will be more extensive. As a professional hot melt adhesive manufacturer, we will continue to be committed to developing more efficient and environmentally friendly hot melt adhesive products to provide better services for automobile manufacturers.

- The difference between C5 petroleum resin and C9 petroleum resin

- Application of hot melt adhesive powder in the garment industry

- 20 years of grinding a sword-"Weiwang Hot Melt Adhesive" one-stop bonding solution expert

- What are the advantages of W9102 hot melt glue stick?

- Weiwang hot melt adhesive company held the kick-off meeting of lean management reform project

- What impact does Xiaomi hot melt glue gun have on Weiwang hot melt glue manufacturer

13802979115

13802979115

2024-12-2

2024-12-2