- 【 Breaking News 】 Chairman Liao Yongping has been honored as the third president of the Guangdong Hunan Linxiang Chamber of Commerce

- Innovation in Bonding in Luggage Production: How does Hot Melt Adhesive Reshape Durability and Production Efficiency

- A new option for fixing Electronic wiring harness terminals: How does hot melt Adhesive Ensure stable connections and efficient production

- New Trends in Shoe material Bonding: How Can Hot melt Adhesive Sticks Enhance Efficiency and empower the Shoe-making industry

- Say goodbye to slow drying and glue overflow! Manual bonding of special hot melt adhesive rods ensures fast and stable production

- Innovating the bonding process of handbags: Hot melt adhesive is a powerful tool to reshape packaging quality and efficiency

- Hot melt adhesive sticks for car dent repair: Revolutionizing traditional techniques, reshaping repair efficiency and quality

- Odorless and no drawing! Exclusive hot melt adhesive sticks for export, unlocking a new experience of efficient bonding

- How does hot melt adhesive empower cost reduction and efficiency improvement in the production of air filter elements

- New EPE pearl cotton bonding solution: Hot melt adhesive particles solve the bonding problems of multi-layer composites and special-shaped materials

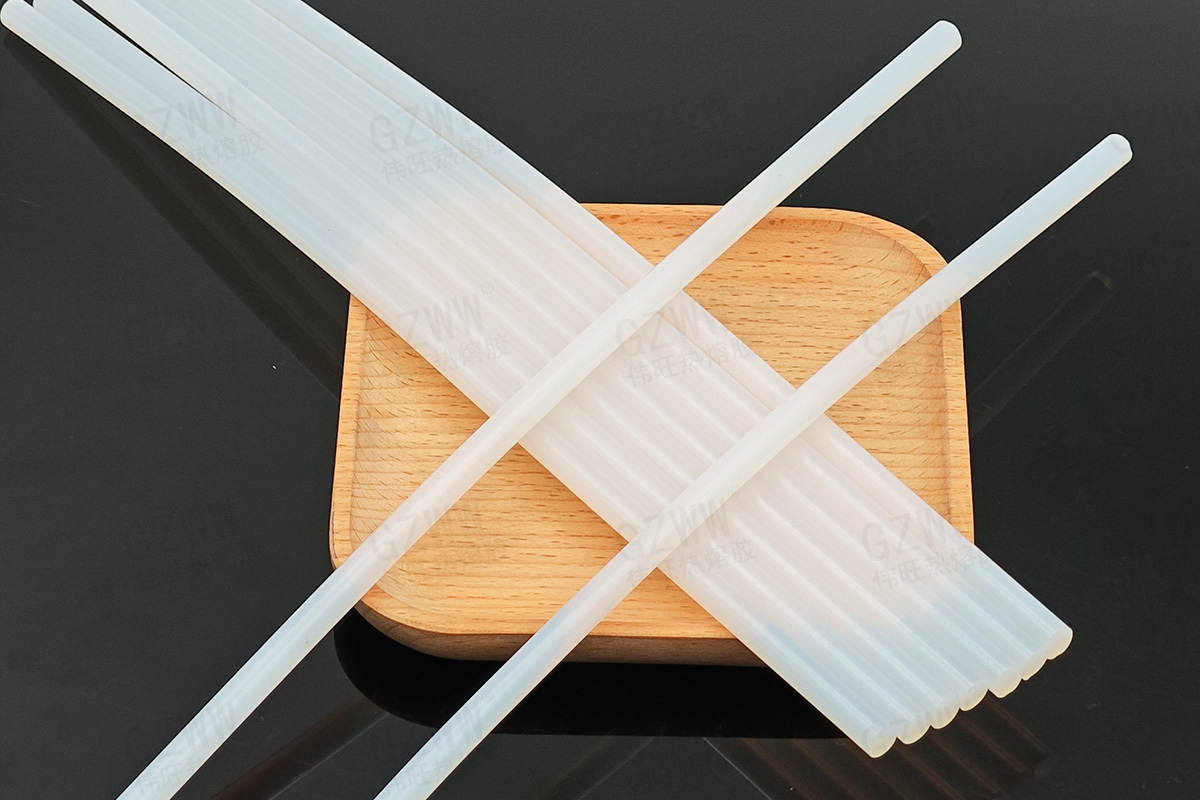

In the production fields of artificial flowers, floor MATS, paper products, etc., traditional adhesives often have problems such as insufficient adhesion, pungent smell, and residue of stringing, which affect product quality and production efficiency. As a professional manufacturer deeply engaged in the hot melt adhesive industry for many years, we are launching a brand-new export-grade high-performance hot melt adhesive rod. With the three core advantages of high adhesion and strength, environmental friendliness and odorlessness, and zero drawing process, it brings more efficient and high-quality bonding solutions to manufacturers and purchasers.

1. Full-scenario adaptation to meet the strict demands of multiple industries

Whether it is the fine bonding of petals and flower stems in the artificial flower industry, the fixation of complex shapes, or the composite splicing of multiple layers of materials and corner reinforcement in the production of floor MATS; Whether it is in the paper products industry for paper lamination or the rapid packaging of gift boxes, this hot melt adhesive stick can be perfectly adapted:

Material compatibility: Compatible with common materials used in the production of artificial flowers, floor MATS and paper products such as plastic, fabric, paper and foam, solving the problem of "material selection" in traditional adhesives.

Process adaptability: Compatible with various hot melt glue guns, automatic dispensing machines and other equipment, supporting both manual operation and automated production lines, meeting the production needs of enterprises of different scales.

Bonding scene coverage: From the precise positioning of tiny components to the rapid bonding of large areas of materials, uniform coating and firm adhesion can be achieved.

Second, three core advantages redefine the bonding standard

High viscosity and strong, durable and long-lasting

Adopting a high-molecular polymerization formula, this hot melt adhesive stick demonstrates an adhesive force far exceeding that of traditional glues. In the production of artificial flowers, even if the petals are frequently bent and shaken, they can still remain firm for a long time. When used for bonding floor MATS, it is not prone to delamination under the pressure of heavy objects and long-term friction. In the field of paper packaging, after multiple moves, the bonding parts remain as stable as ever, significantly reducing the after-sales return rate of the products.

2. Export-oriented quality, environmentally friendly and odorless

It is strictly produced in accordance with international environmental protection standards and has passed multiple authoritative certifications such as ROHS and REACH, ensuring that no irritating odors are released during production and use. It is particularly suitable for export-oriented enterprises, meeting the strict requirements for environmentally friendly materials in regions such as Europe, America, Japan and South Korea, and helping enterprises easily pass overseas customer factory audits and expand into international markets.

3. Zero wire drawing process enhances production efficiency and product aesthetics

Unlike traditional adhesives that are prone to problems such as stringing and sticking, hot melt adhesive sticks have uniform fluidity after melting and break the glue neatly and smoothly. When making artificial flowers, the shape and color of the petals will not be affected by the stringing. During the production process of floor MATS, there is no need for manual cleaning of residual threads, reducing equipment maintenance time. After the paper product packaging is completed, the surface is clean and tidy without any glue residue, effectively enhancing the appearance texture of the product and production efficiency.

Third, compared with traditional adhesives, it leads comprehensively in four major dimensions

Traditional glue has many drawbacks in the bonding of artificial flowers, floor MATS and paper products. In terms of adhesive force, traditional glue has weak initial adhesion, requires a long waiting time for curing, and is prone to delamination in the later stage. In terms of odor, it contains a large amount of volatile organic solvents, which not only pollutes the workshop environment but also may cause the products to fail the export quality inspection due to odor issues. The wire drawing problem increases the cost of manual cleaning and time, affecting the production progress. In addition, traditional adhesives have poor compatibility with different materials, often resulting in weak bonding or material corrosion.

Our hot melt adhesive sticks have achieved a breakthrough in all aspects. The high viscosity property ensures immediate adhesion and firmness, significantly shortening the production cycle. Environmentally friendly and odorless, it completely solves the odor problem and meets domestic and international environmental protection standards. The zero wire drawing process simplifies the production process and reduces labor and equipment maintenance costs. The extensive material compatibility is suitable for various production needs, reducing production risks caused by improper selection of adhesives and lowering the comprehensive usage costs of enterprises.

Fourth, professional services ensure a smooth cooperation

As industry veterans who have been deeply involved in the hot melt adhesive field for many years, we are well aware of the significance of production stability and product quality to enterprises. To this end, we have established a complete service system: providing free customized sample services. According to the actual materials and processes used by enterprises, we can specifically adjust samples to allow enterprises to directly experience the performance of the products. Equipped with a professional technical team, we provide one-on-one guidance throughout the process from equipment debugging, parameter setting to technical problems in the production process to ensure seamless production connection. We strictly control product quality. Each batch of hot melt adhesive rods must go through multiple quality inspection procedures and third-party authoritative tests to lay a solid foundation for the enterprise's production with reliable quality.

- What can Weiwang hot melt adhesive stick to?

- Life magic of hot melt adhesive

- Advantages of using hot melt adhesive rods? Is there a requirement for ambient temperature?

- Look!! Hot melt glue is actually an environmentally friendly tool!

- The Widespread Use of Hot Melt Adhesive Bars

- Hot Melt Adhesive: The Mystery of Adhesion, Taking You to Deeply Understand“

13802979115

13802979115

2025-5-12

2025-5-12