- 【 Breaking News 】 Chairman Liao Yongping has been honored as the third president of the Guangdong Hunan Linxiang Chamber of Commerce

- Innovation in Bonding in Luggage Production: How does Hot Melt Adhesive Reshape Durability and Production Efficiency

- A new option for fixing Electronic wiring harness terminals: How does hot melt Adhesive Ensure stable connections and efficient production

- New Trends in Shoe material Bonding: How Can Hot melt Adhesive Sticks Enhance Efficiency and empower the Shoe-making industry

- Say goodbye to slow drying and glue overflow! Manual bonding of special hot melt adhesive rods ensures fast and stable production

- Innovating the bonding process of handbags: Hot melt adhesive is a powerful tool to reshape packaging quality and efficiency

- Hot melt adhesive sticks for car dent repair: Revolutionizing traditional techniques, reshaping repair efficiency and quality

- Odorless and no drawing! Exclusive hot melt adhesive sticks for export, unlocking a new experience of efficient bonding

- How does hot melt adhesive empower cost reduction and efficiency improvement in the production of air filter elements

- New EPE pearl cotton bonding solution: Hot melt adhesive particles solve the bonding problems of multi-layer composites and special-shaped materials

In today's rapidly developing automotive industry, the quality and beauty of the interior has become one of the important factors for consumers to choose models. As an innovative bonding material, hot melt adhesive is setting off a new trend in the automotive interior bonding industry with its unique advantages.

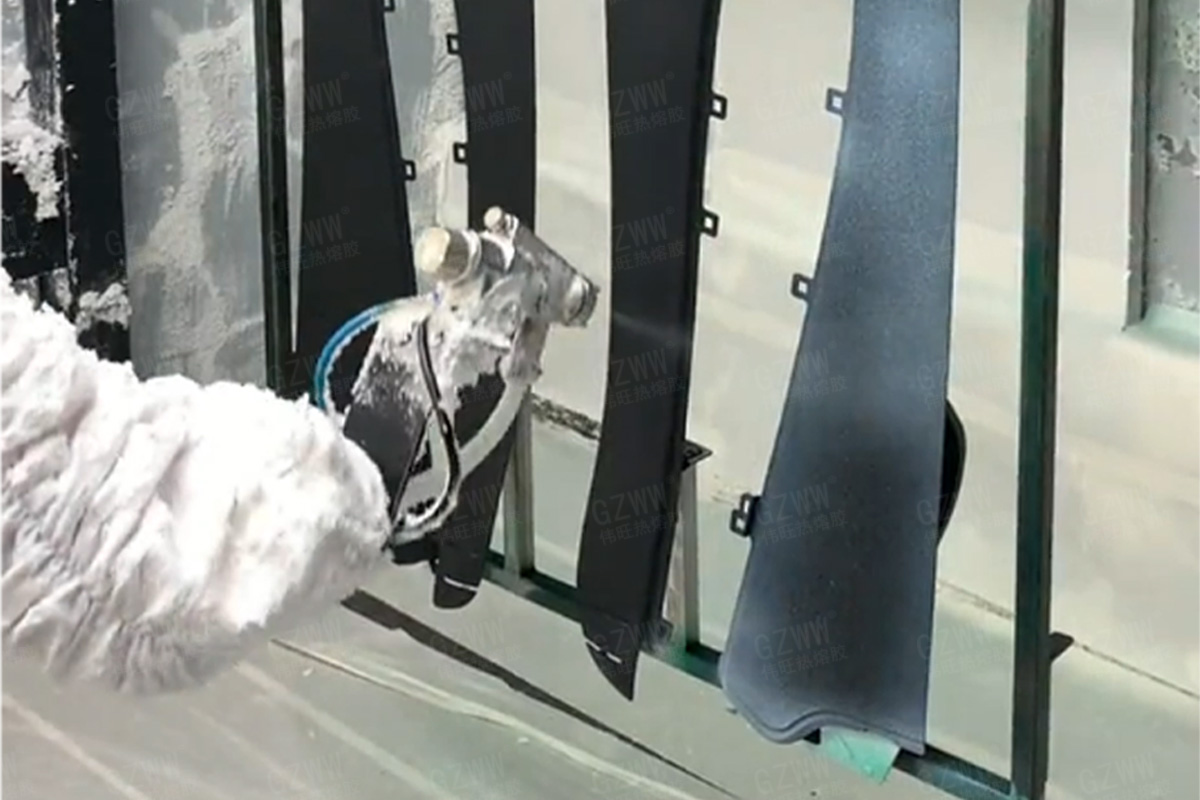

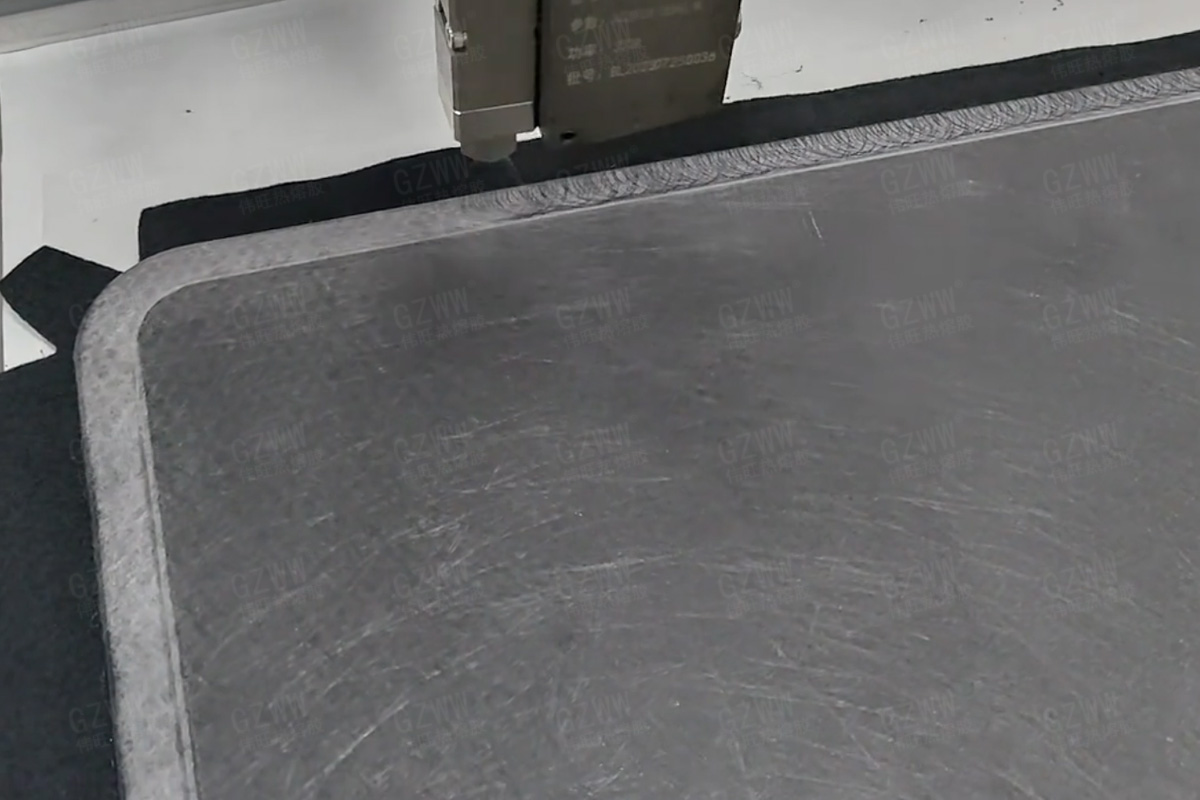

Deep application, improve the interior quality

In the field of automotive interior bonding, the application of hot melt adhesive can be described as everywhere. From the bonding of the ceiling, the fixing of the interior parts, to the laying of the carpet and floor insulation MATS, and then to the sound insulation sealing of high-end automotive components, hot melt adhesives play an irreplaceable role. It can not only effectively bond PP, ABS, plastics, non-woven fabrics and other materials, but also ensure that the interior parts can maintain stability and durability in a variety of environments because of its good resistance to high and low temperatures.

Environmental protection and non-toxic, in line with the concept of green manufacturing

With the improvement of environmental awareness, the environmental protection of automotive interior materials has been paid more and more attention. As an environmentally friendly non-toxic adhesive, hot melt adhesive perfectly fits the modern green manufacturing concept. Compared with traditional solvent-based adhesives, hot melt adhesives do not need ventilation to dry solvents, greatly improving the working environment, reducing VOC (volatile organic compounds) emissions, and harmless to the health of the operator and the air quality in the car.

Efficient and convenient, help automated production

Hot melt adhesive curing speed, convenient construction, very suitable for high-speed automated production. In the automotive interior manufacturing process, the use of hot melt adhesive can significantly improve production efficiency and reduce labor costs.

Diversified choices to meet individual needs

With the increasing demand for diversification and personalization of automotive interiors, the color and texture of hot melt adhesives are constantly updated and optimized. Manufacturers can choose different types and properties of hot melt adhesives according to the characteristics and uses of interior materials to meet the diversified needs of customers. This flexibility makes hot melt adhesives more competitive in the automotive interior bonding industry.

With its excellent performance and wide application prospects, hot melt adhesive is gradually becoming the preferred material in the automotive interior bonding industry. In the future, with the continuous progress of science and technology and the increasing requirements of environmental protection, the application of hot melt adhesive in automotive interior manufacturing will be more extensive and in-depth. Let's look forward to more innovations and changes brought by hot melt adhesives for the automotive interior industry!

13802979115

13802979115

2024-9-13

2024-9-13