- New Solution for Pearl Cotton Bonding: How does Hot melt Adhesive Address Processing Pain Points and Enhance Production Efficiency

- 【 Breaking News 】 Chairman Liao Yongping has been honored as the third president of the Guangdong Hunan Linxiang Chamber of Commerce

- Innovation in Bonding in Luggage Production: How does Hot Melt Adhesive Reshape Durability and Production Efficiency

- A new option for fixing Electronic wiring harness terminals: How does hot melt Adhesive Ensure stable connections and efficient production

- New Trends in Shoe material Bonding: How Can Hot melt Adhesive Sticks Enhance Efficiency and empower the Shoe-making industry

- Say goodbye to slow drying and glue overflow! Manual bonding of special hot melt adhesive rods ensures fast and stable production

- Innovating the bonding process of handbags: Hot melt adhesive is a powerful tool to reshape packaging quality and efficiency

- Hot melt adhesive sticks for car dent repair: Revolutionizing traditional techniques, reshaping repair efficiency and quality

- Odorless and no drawing! Exclusive hot melt adhesive sticks for export, unlocking a new experience of efficient bonding

- How does hot melt adhesive empower cost reduction and efficiency improvement in the production of air filter elements

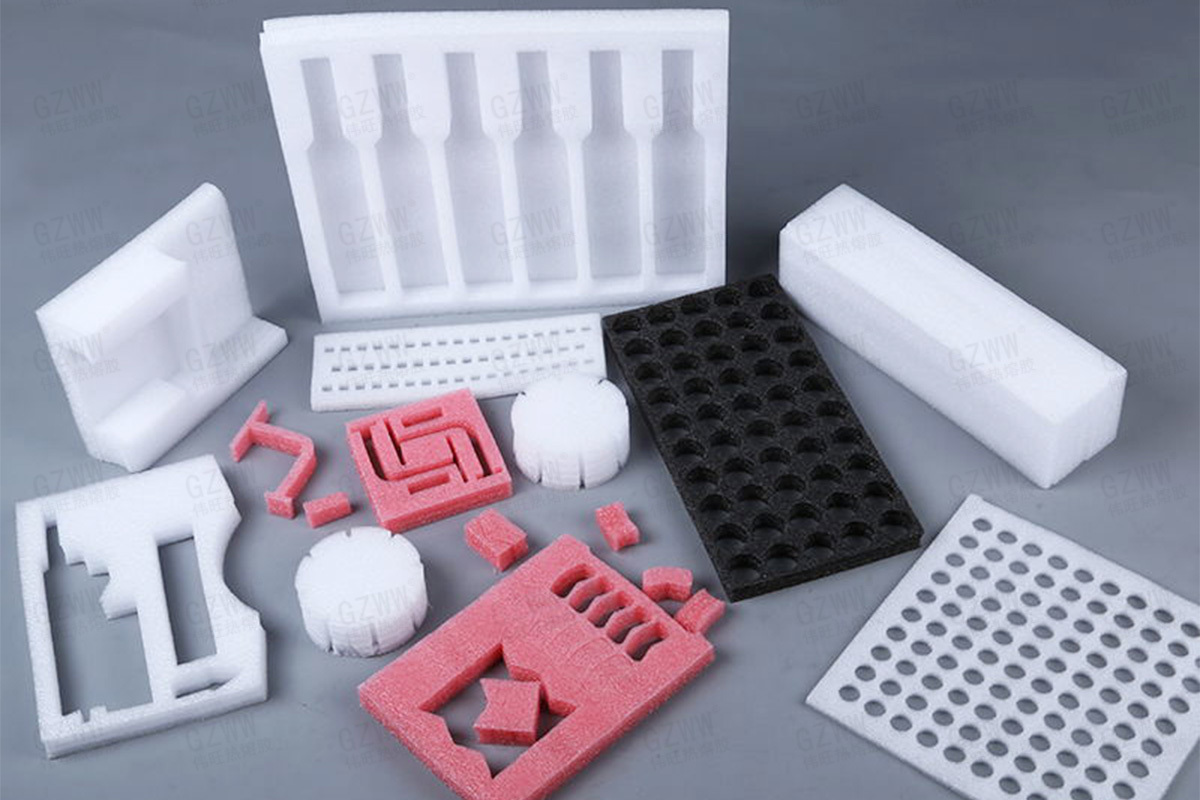

In the production and processing of EPE (Pearl Cotton), from the splicing of packaging linings to the composite of profiled materials, the quality of the bonding process directly affects product quality and production efficiency. Traditional adhesives have problems such as strong odor, severe stringing and slow curing. However, the hot melt adhesive specially developed for pearl cotton, with its core advantages of low odor, no stringing, fast curing and strong adhesion, is becoming a key choice for industry upgrading.

The four core advantages of pearl cotton hot melt adhesive precisely match processing requirements

1. Low odor characteristics optimize the production environment

Hot melt adhesive is made from environmentally friendly base materials and does not contain volatile harmful solvents. During the application process, there is almost no pungent odor. This not only enables workers to operate in a comfortable environment, reducing respiratory discomfort, but also avoids the impact of odor residue on the application of pearl cotton in sensitive fields such as food and electronics caused by traditional glue, broadening the application scenarios of the product.

2. Non-brushing design ensures processing cleanliness

When traditional glue is applied and bonded, it is prone to stringing, resulting in residual glue threads on the surface of pearl cotton. This not only affects the appearance but also requires additional manual cleaning. Hot melt adhesive, through a specially designed formula, breaks smoothly after application without any excess glue residue, ensuring a smooth and clean bonding surface. This eliminates the need for post-treatment processes and reduces labor costs.

3. Rapid curing significantly enhances production efficiency

After the hot melt adhesive is heated and melted, it can complete the curing of the pearl cotton material in just a few seconds upon contact. Compared with the drying time of traditional adhesives that requires tens of minutes or even several hours, it can significantly shorten the production cycle. Take the splicing of pearl cotton packaging inner lining as an example. The use of hot melt adhesive can reduce the processing time of a single batch of products by more than 50%, easily meeting the demands of large orders.

4. Strong adhesive force ensures a firm bond

Hot melt adhesive can form a tight molecular-level bond with pearl cotton. Even under force pulling or long-term use, it is not easy to delaminate or fall off. Whether it is the bonding of thin and light pearl cotton sheets or the composite of thick and special-shaped materials, it can maintain a stable bonding effect, enhancing the structural strength and durability of pearl cotton products.

Ii. The Practical Value that hot melt Adhesive brings to the pearl Cotton Industry

1. Improve the production environment and reduce health risksThe low-odor feature reduces the emission of harmful gases in the workshop, eliminating the need for additional complex ventilation equipment and lowering the enterprise's investment in environmental protection facilities. At the same time, protect workers' health and reduce the employment risks caused by occupational health issues.

2. Simplify the production process to enhance efficiency and quality

The non-threading feature eliminates the need for glue thread cleaning, and the rapid curing shortens the production cycle, enabling enterprises to produce more products within the same period of time. The smooth and clean bonding surface also enhances the appearance quality of pearl cotton products and strengthens their competitiveness in the market.

3. Expand application fields and increase profit margins

As hot melt adhesive is environmentally friendly and odorless, the pearl cotton products bonded can be safely used in high-end fields such as food packaging, medical supplies, and precision electronic accessories, helping enterprises break through application limitations and enter high-value-added markets.

4. Reduce the overall cost and increase the profit level

Rapid curing reduces the cost of equipment and site occupation, no stringing lowers the defect rate and rework cost, and strong adhesive force reduces the losses caused by after-sales problems. Multiple cost optimizations enable enterprises to have a greater price advantage in the fierce market competition.

Conclusion

Under the development trend of the pearl cotton industry that pursues high efficiency, environmental protection and high quality, hot melt adhesive, with its advantages of low odor, no stringing, rapid curing and strong adhesion, is gradually replacing traditional glue and becoming the preferred solution in the processing stage. As a professional hot melt adhesive manufacturer, we are committed to providing customized products for pearl cotton production and processing enterprises, helping them solve processing pain points, improve production efficiency, and gain a favorable position in market competition.

- New Trends in Shoe material Bonding: How Can Hot melt Adhesive Sticks Enhance Efficiency and empower the Shoe-making industry

- New Solution for Pearl Cotton Bonding: How does Hot melt Adhesive Address Processing Pain Points and Enhance Production Efficiency

- Weiwang hot melt adhesive tape, you witness the 2020 (16th) China Hot Melt Adhesive Professional Summit Forum

- 20 years of grinding a sword-"Weiwang Hot Melt Adhesive" one-stop bonding solution expert

- Xiaomi Youpin has started to make hot melt glue guns. What impact does this have on the traditional hot melt glue market?

- What are the advantages of W9102 hot melt glue stick?

13802979115

13802979115

2025-7-9

2025-7-9