- New Solution for Pearl Cotton Bonding: How does Hot melt Adhesive Address Processing Pain Points and Enhance Production Efficiency

- 【 Breaking News 】 Chairman Liao Yongping has been honored as the third president of the Guangdong Hunan Linxiang Chamber of Commerce

- Innovation in Bonding in Luggage Production: How does Hot Melt Adhesive Reshape Durability and Production Efficiency

- A new option for fixing Electronic wiring harness terminals: How does hot melt Adhesive Ensure stable connections and efficient production

- New Trends in Shoe material Bonding: How Can Hot melt Adhesive Sticks Enhance Efficiency and empower the Shoe-making industry

- Say goodbye to slow drying and glue overflow! Manual bonding of special hot melt adhesive rods ensures fast and stable production

- Innovating the bonding process of handbags: Hot melt adhesive is a powerful tool to reshape packaging quality and efficiency

- Hot melt adhesive sticks for car dent repair: Revolutionizing traditional techniques, reshaping repair efficiency and quality

- Odorless and no drawing! Exclusive hot melt adhesive sticks for export, unlocking a new experience of efficient bonding

- How does hot melt adhesive empower cost reduction and efficiency improvement in the production of air filter elements

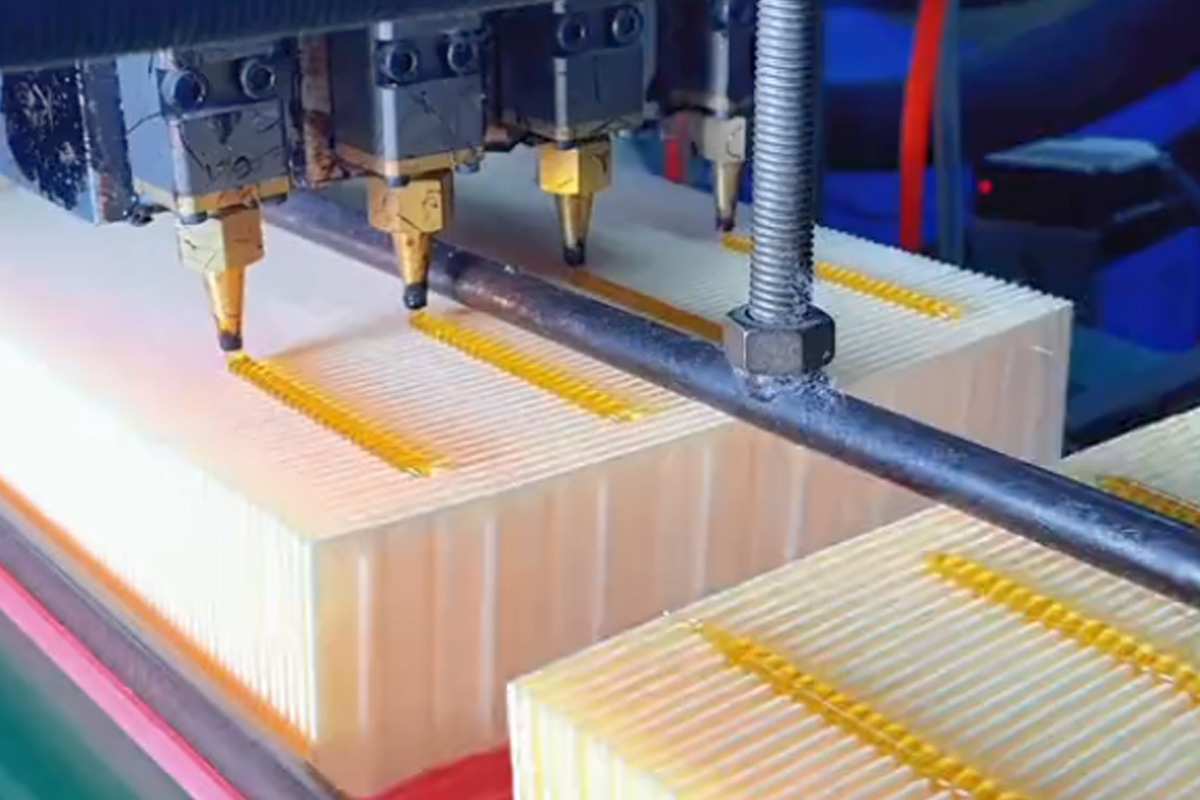

At the broken line of the filter element, it can firmly bond the parts of different materials together to ensure that there will be no problems such as ungluing and degluing during the use of the filter element. After rigorous testing, its bonding force far exceeds the traditional bonding material, providing a strong guarantee for the stability and reliability of the filter element.

The curing speed of hot melt adhesive is fast, which is of great significance in the production of filter element. On busy production lines, the fast curing hot melt adhesive can quickly complete the bonding process, reduce the waiting time in the production process, and improve the overall production efficiency. At the same time, this also helps enterprises to produce more high-quality filter products in a short time to meet the needs of the market.

In addition, the special hot melt adhesive for the filter element also has good temperature resistance. In the high temperature industrial environment, the hot melt adhesive can maintain stable performance to ensure that the adhesion of the filter element will not be degumming, cracking and other problems due to temperature changes, so as to ensure the filter effect and service life of the filter element.

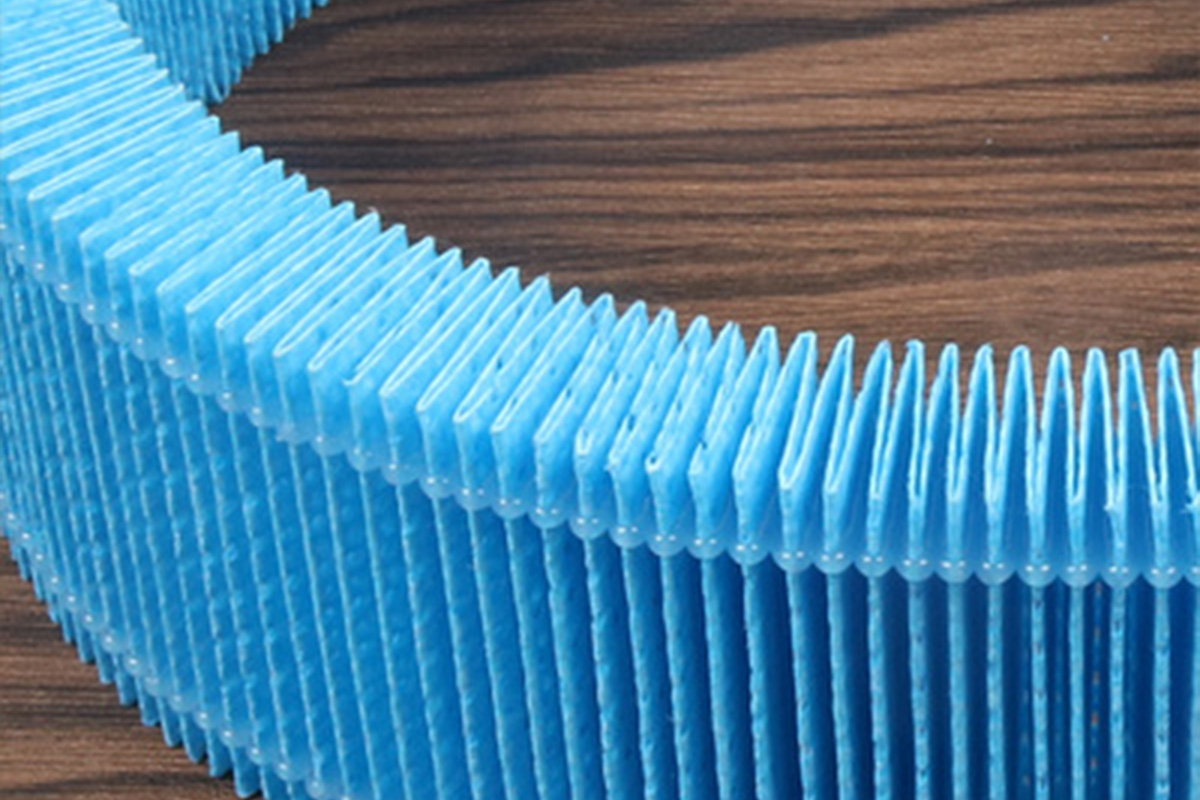

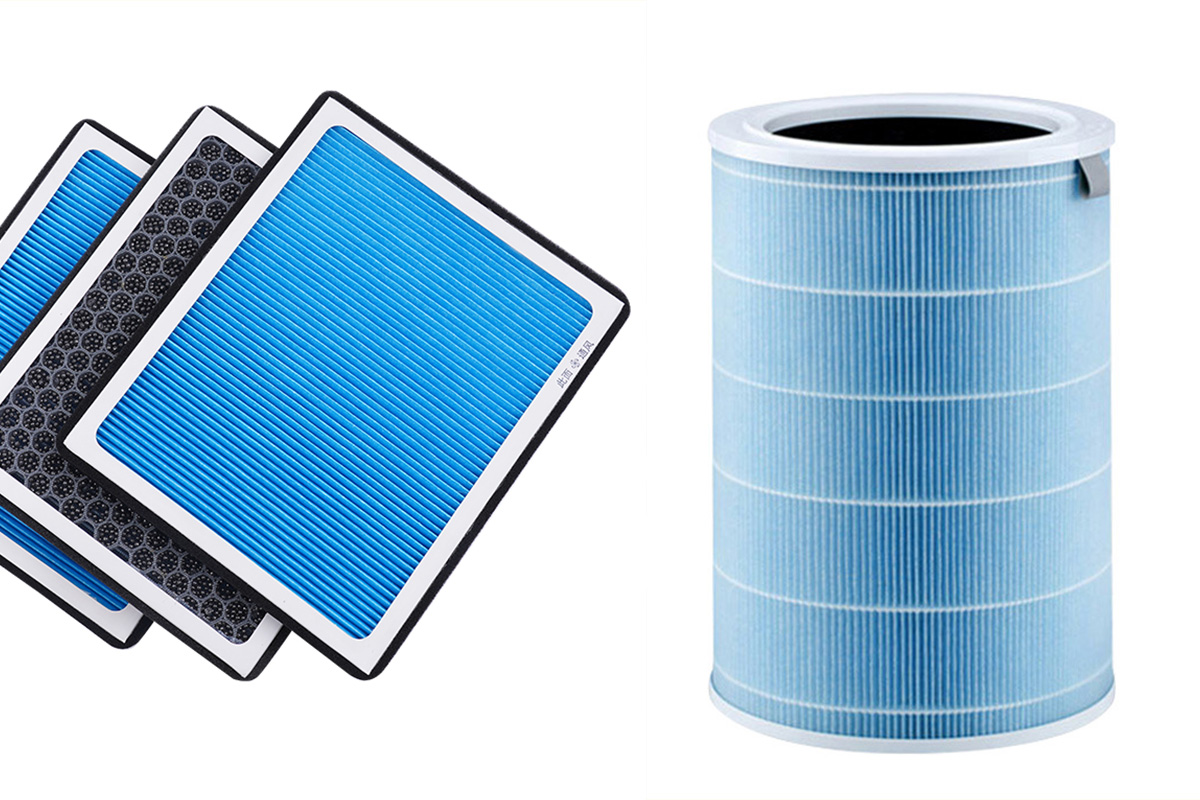

The special hot melt adhesive for filter line has good adaptability and can be applied to different materials and different shapes of filter element. Whether it is round filter, square filter or other special shape filter, it can achieve good bonding effect.

It is worth mentioning that the environmental protection of hot melt adhesive also meets the development needs of modern society. It does not use any solvent in the production and use process, is non-toxic and tasteless, does not release harmful substances, and has no harm to human health and the environment, which makes the filter made of hot melt adhesive more advantageous in environmental protection.

In summary, hot melt adhesive with its strong adhesive force, rapid curing and other advantages, has become the right-hand man of filter element manufacturing. It is believed that in the field of filter element manufacturing in the future, hot melt adhesive will continue to play an important role and make greater contributions to improving the quality and performance of filter element.

- Hot melt adhesive particles: a comprehensive analysis from raw materials to applications

- Let's learn about hot melt adhesive particles together

- Can hot melt adhesive still be used in car headlights?

- What are the advantages of hot melt adhesive particles?

- Can hot melt glue sticks be used in the wreath industry?

- Is there a relationship between the adhesion of handbags and hot melt adhesive particles?

13802979115

13802979115

2024-12-23

2024-12-23