- 【 Breaking News 】 Chairman Liao Yongping has been honored as the third president of the Guangdong Hunan Linxiang Chamber of Commerce

- Innovation in Bonding in Luggage Production: How does Hot Melt Adhesive Reshape Durability and Production Efficiency

- A new option for fixing Electronic wiring harness terminals: How does hot melt Adhesive Ensure stable connections and efficient production

- New Trends in Shoe material Bonding: How Can Hot melt Adhesive Sticks Enhance Efficiency and empower the Shoe-making industry

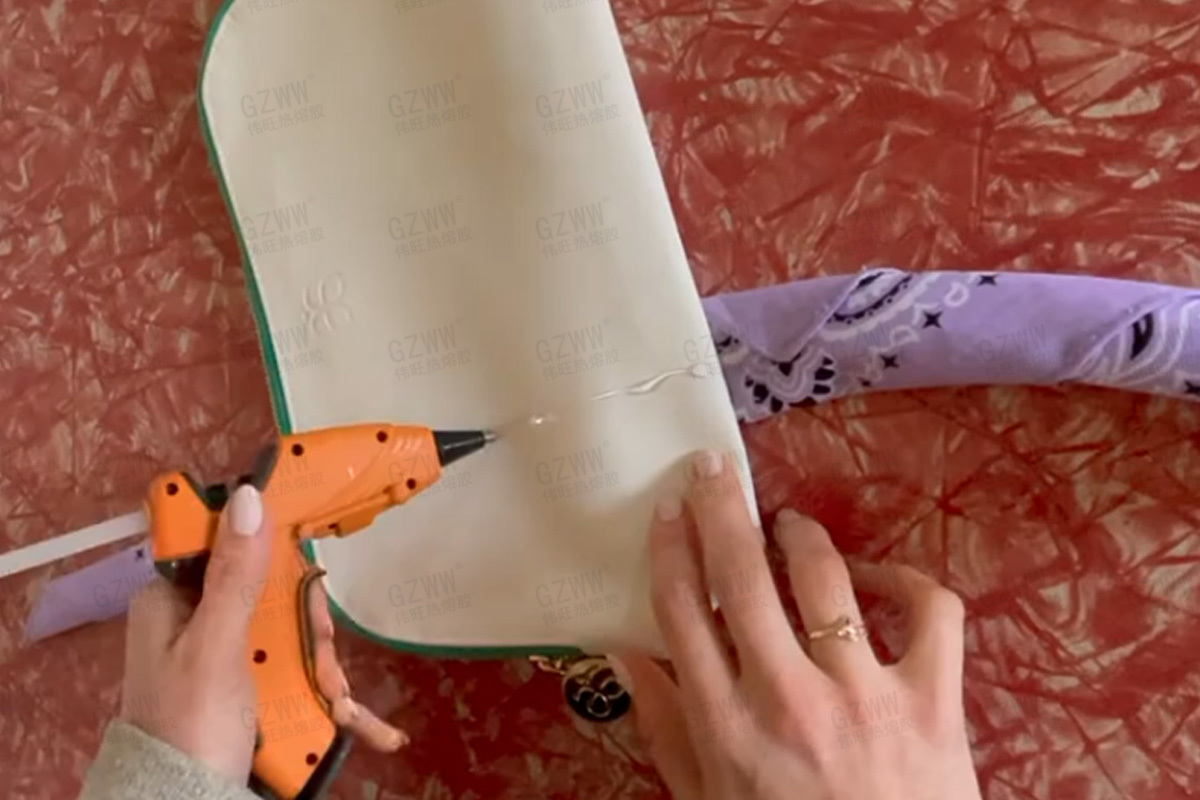

- Say goodbye to slow drying and glue overflow! Manual bonding of special hot melt adhesive rods ensures fast and stable production

- Innovating the bonding process of handbags: Hot melt adhesive is a powerful tool to reshape packaging quality and efficiency

- Hot melt adhesive sticks for car dent repair: Revolutionizing traditional techniques, reshaping repair efficiency and quality

- Odorless and no drawing! Exclusive hot melt adhesive sticks for export, unlocking a new experience of efficient bonding

- How does hot melt adhesive empower cost reduction and efficiency improvement in the production of air filter elements

- New EPE pearl cotton bonding solution: Hot melt adhesive particles solve the bonding problems of multi-layer composites and special-shaped materials

With the continuous progress of science and technology and the increasing diversification of consumer demand, the application prospect of hot melt adhesive in the field of textile bonding is more and more broad. It not only simplifies the bonding process, improves work efficiency, but also represents the future development trend, and has injected a strong impetus into the development of the textile industry.

The specific application advantages of hot melt adhesive in textiles

Increased production efficiency: The instant curing properties of hot melt adhesives make the textile bonding process more efficient. In the automated production line, the hot melt adhesive machine can quickly and accurately complete the bonding work, which greatly improves the production efficiency.

Environmental safety, health protection: hot melt adhesive made of environmentally friendly materials, non-toxic and tasteless, does not produce harmful gases, providing the operator with a safe and healthy working environment, but also in line with the green production concept of modern society.

Optimize product quality: The adhesive layer formed by the hot melt adhesive is strong and durable, ensuring that the textile remains stable in long-term use. This high quality bonding effect helps to improve the overall quality and market competitiveness of textiles.

Promote creative realization: The wide compatibility and fine handling characteristics of hot melt adhesives provide craftspeople with more creative possibilities. They can freely combine and splice textiles of different materials, colors and textures to achieve more complex and unique design ideas.

The application of hot melt adhesives in textiles is quite extensive, covering almost all textile fields that need bonding

Special function textiles: With the progress of science and technology, more and more textiles have been given special functions, such as waterproof, breathable, warm and so on. Hot melt adhesives also play an important role in the production of these special functional textiles, ensuring a strong bond between the various functional layers and the substrate.

Medical textiles: Hot melt adhesives are also widely used in the field of medical textiles, such as medical dressings, surgical gowns, masks, etc. Because hot melt adhesive has the characteristics of non-toxic, tasteless, environmental protection, so the application in the field of medical and health has attracted more and more attention.

Non-woven fabric: Hot melt adhesive is also widely used in the manufacture of non-woven fabric. These non-woven fabrics are widely used as clothing linings, children's diapers, medical materials, filter materials, polishing, table cloth, blankets, synthetic leather, insulation cloth and so on.

The wide application and continuous innovation of hot melt adhesives in the field of textile bonding have injected new vitality into the development of the textile industry. It not only improves production efficiency, optimizes product quality, promotes creative realization, but also promotes the intelligent transformation and sustainable development of the industry. In the future, with the continuous progress of hot melt adhesive technology and the continuous expansion of application fields, we have reason to believe that hot melt adhesive will continue to play an important role in the textile industry and lead the innovative development trend of the industry.

- Weiwang hot melt adhesive manufacturer teaches you to use the folding edge of air filter element

- What are the purchase methods of Weiwang hot melt glue stick

- How about the application of hot-melt adhesive to automobiles?

- How to enhance the viscosity of hot melt adhesives?

- How do you divide hot melt adhesive? What else besides EVA?

- Hot melt adhesive doesn't stick? Try these measures to improve bonding strength

13802979115

13802979115

2024-8-31

2024-8-31