- 【 Breaking News 】 Chairman Liao Yongping has been honored as the third president of the Guangdong Hunan Linxiang Chamber of Commerce

- Innovation in Bonding in Luggage Production: How does Hot Melt Adhesive Reshape Durability and Production Efficiency

- A new option for fixing Electronic wiring harness terminals: How does hot melt Adhesive Ensure stable connections and efficient production

- New Trends in Shoe material Bonding: How Can Hot melt Adhesive Sticks Enhance Efficiency and empower the Shoe-making industry

- Say goodbye to slow drying and glue overflow! Manual bonding of special hot melt adhesive rods ensures fast and stable production

- Innovating the bonding process of handbags: Hot melt adhesive is a powerful tool to reshape packaging quality and efficiency

- Hot melt adhesive sticks for car dent repair: Revolutionizing traditional techniques, reshaping repair efficiency and quality

- Odorless and no drawing! Exclusive hot melt adhesive sticks for export, unlocking a new experience of efficient bonding

- How does hot melt adhesive empower cost reduction and efficiency improvement in the production of air filter elements

- New EPE pearl cotton bonding solution: Hot melt adhesive particles solve the bonding problems of multi-layer composites and special-shaped materials

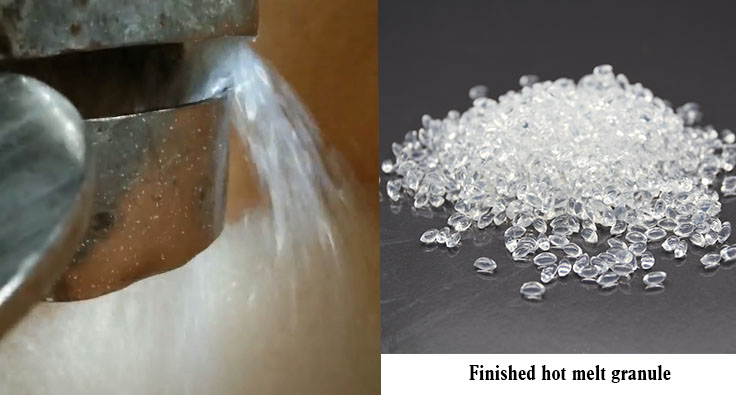

The hot melt adhesive material is stirred in the reaction vessel. After stirring, put the stirred hot melt glue into the storage tank and add some additives to stir again. Don't forget to add an extruder under the tank. Under the extrusion of the pellets, this part of the underwater pelletizing is very critical, to be cooled with ice water, so a chiller is required. After the underwater pelletizing is completed, it is necessary to dry the water to the dryer and then transfer it to the vibrating screen to select it. After the brush is selected, the surface of the particles is rough, so it is necessary to add powder to stir and polish. After the polishing is completed, it is the packaging part. The above is a simple process for the production of hot melt pellets.

- Advantages of large sealing hot melt adhesive

- Do you know how many Weiwang hot melt sticks there are?

- What are the advantages of Weiwang hot melt adhesive carton sealing

- What are the types of hot melt adhesives

- Life magic of hot melt adhesive

- The advantages of hot melt adhesive and its influencing factors

13802979115

13802979115

2019-5-24

2019-5-24