- 【 Breaking News 】 Chairman Liao Yongping has been honored as the third president of the Guangdong Hunan Linxiang Chamber of Commerce

- Innovation in Bonding in Luggage Production: How does Hot Melt Adhesive Reshape Durability and Production Efficiency

- A new option for fixing Electronic wiring harness terminals: How does hot melt Adhesive Ensure stable connections and efficient production

- New Trends in Shoe material Bonding: How Can Hot melt Adhesive Sticks Enhance Efficiency and empower the Shoe-making industry

- Say goodbye to slow drying and glue overflow! Manual bonding of special hot melt adhesive rods ensures fast and stable production

- Innovating the bonding process of handbags: Hot melt adhesive is a powerful tool to reshape packaging quality and efficiency

- Hot melt adhesive sticks for car dent repair: Revolutionizing traditional techniques, reshaping repair efficiency and quality

- Odorless and no drawing! Exclusive hot melt adhesive sticks for export, unlocking a new experience of efficient bonding

- How does hot melt adhesive empower cost reduction and efficiency improvement in the production of air filter elements

- New EPE pearl cotton bonding solution: Hot melt adhesive particles solve the bonding problems of multi-layer composites and special-shaped materials

In today's rapidly developing logistics industry, the efficiency and stability of carton sealing has become one of the key factors of enterprise competitiveness. As a professional manufacturer in the field of hot melt adhesive, our fast sealing hot melt adhesive pellets are leading the new revolution of carton sealing technology with its unique advantages.

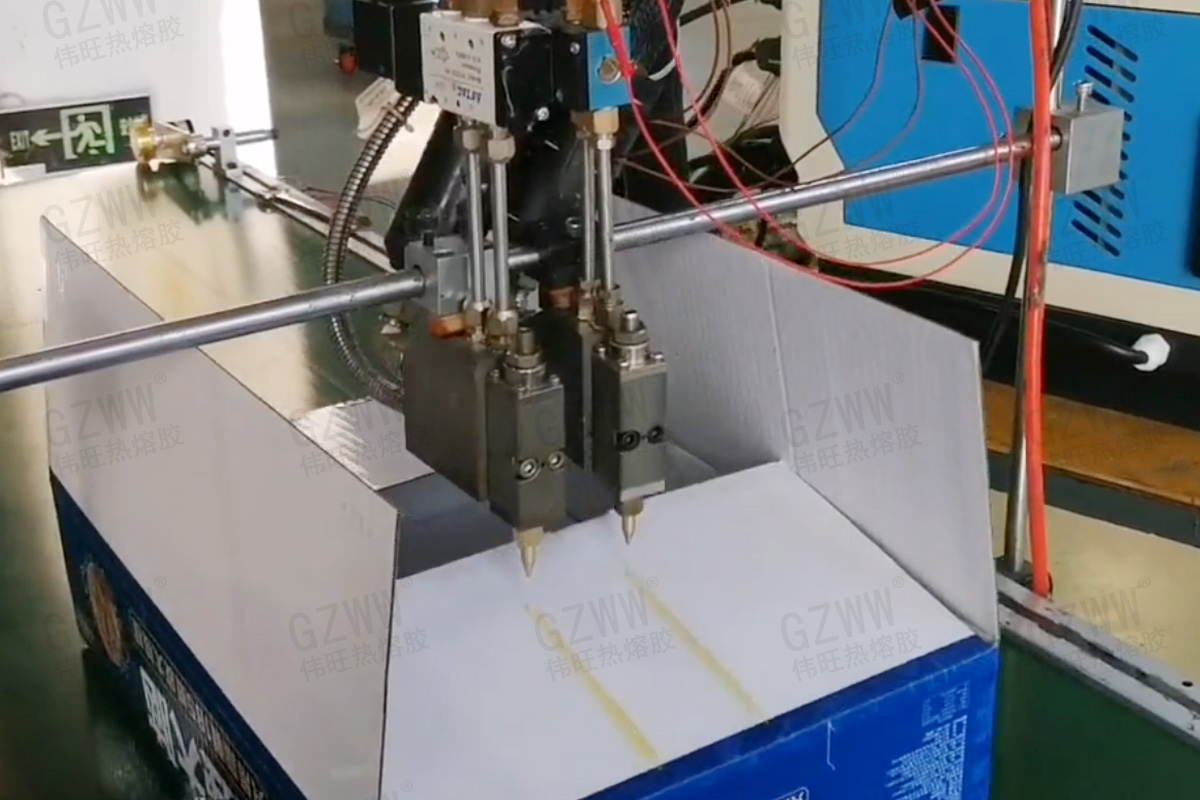

Efficient and fast bonding technology

Fast sealing hot melt pellets, the use of advanced production technology, through the hot melt machine to melt the pellets into liquid, and then spray evenly on the surface of the carton by the spray gun, after cooling can complete the bonding. The whole process takes only 1-3 seconds, greatly improving production efficiency. Compared to traditional tape, hot melt pellets are bonded faster and do not require additional tape cutting and pasting steps, thus reducing labor and time costs.

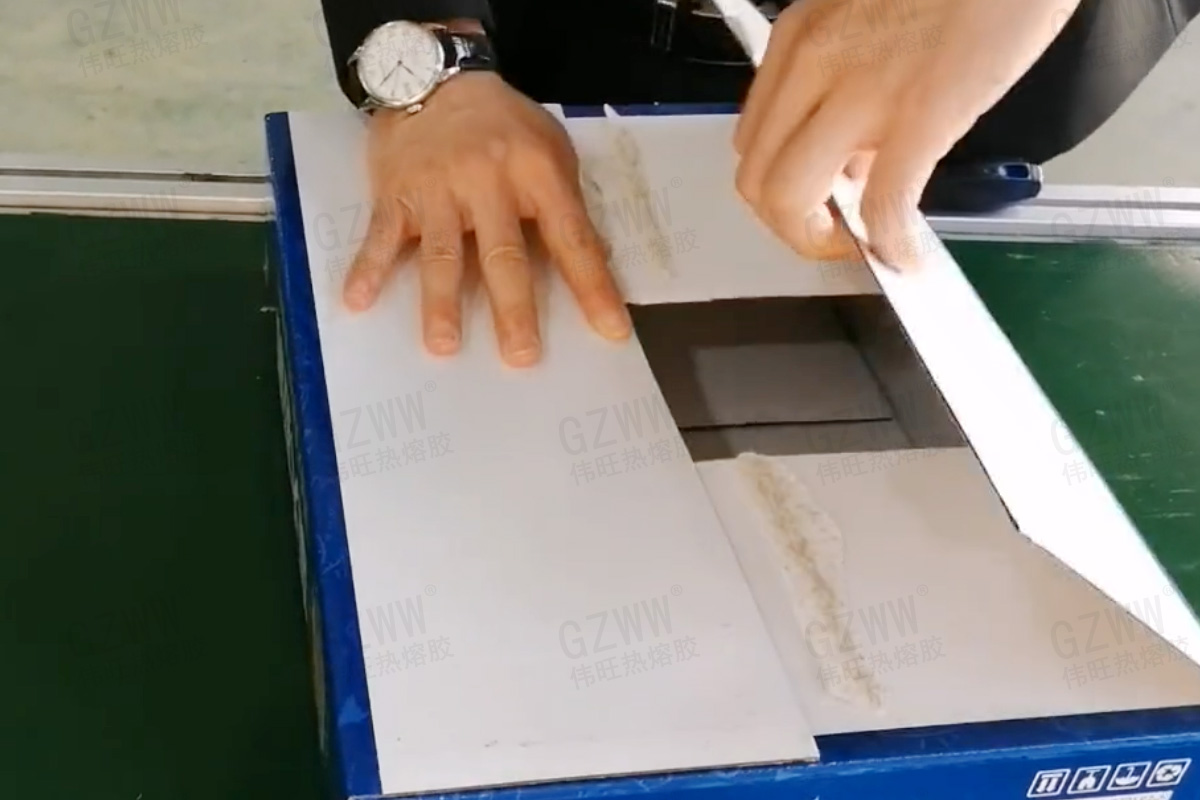

Excellent bonding properties

Hot melt pellets have excellent bonding properties. The adhesive force is strong and can be tightly fitted to the surface of the carton to prevent cracking or deformation of the carton caused by vibration or impact during transportation. At the same time, the curing speed of the hot melt pellets is fast, and the stable bonding effect can be achieved in a short time to ensure the integrity of the carton. In addition, hot melt pellets also have water resistance, moisture resistance, low temperature resistance and other properties, even in wet or low temperature environment, can maintain a stable bonding effect.

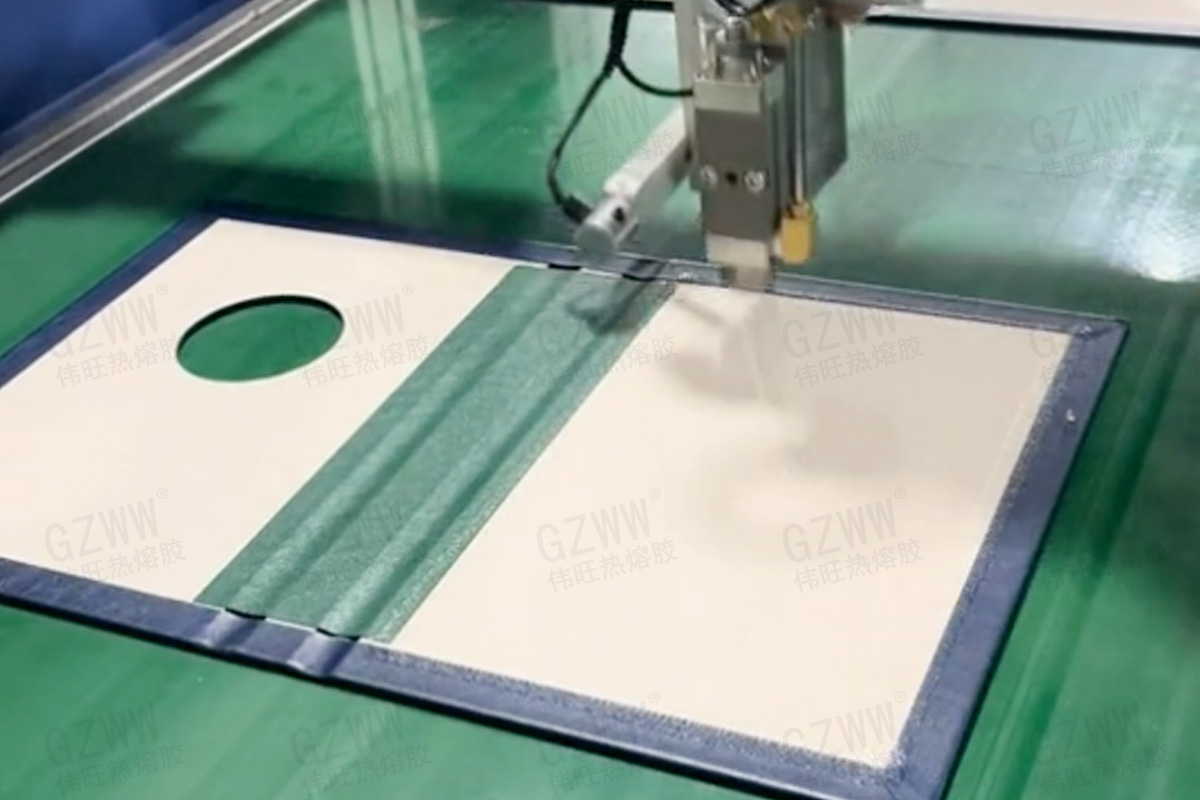

A wide range of applications and market demand

The application of quick-sealing hot-melt rubber granules in the field of gift boxes and food packaging cartons is particularly prominent. In the gift box packaging, the hot melt rubber granules can not only provide a strong bonding effect to ensure the integrity of the gift box during transportation, but also improve the overall beauty of the gift box because of its seamless and beautiful bonding characteristics. In food packaging boxes, the environmental protection and non-toxic characteristics of hot melt pellets have become an important choice factor. It can ensure that the food is not contaminated during the packaging process and protect the health and safety of consumers. In addition, fast sealing hot melt pellets are also widely used in various industrial packaging boxes, electronic product packaging, book binding, medical packaging and other fields. With the continuous improvement of packaging quality and efficiency requirements in various industries, the market demand for fast sealing hot melt pellets is also continuing to grow.

The green advantage of environmental protection and energy saving

As an environmentally friendly chemical product, hot melt pellets are non-toxic, tasteless and harmless to human body. In the production process, hot melt pellets will not produce pollutants, and will not pollute the environment. At the same time, the use of hot melt pellets can also reduce waste generation and reduce transportation and storage costs. This green and environmental protection characteristics make hot melt pellets play an important role in promoting the green development of the industry.

Promote industry development and technological progress

The introduction of fast sealing hot melt pellets not only improves the overall level of carton sealing technology, but also promotes the rapid development of related industries. We are committed to technological innovation and product development, and constantly optimize the performance of fast sealing hot melt pellets to meet the market demand for efficient, environmentally friendly and low-cost bonding technology. At the same time, we will also actively explore the application of hot melt pellets in more fields, and contribute to the sustainable development of the industry.

- Mattress composite bonding: the magic of hot melt adhesive particles

- The advantages of hot melt adhesive in mattress bonding applications are gradually emerging

- Hot melt adhesive: the trusted choice of the logistics carton industry, double effect to improve safety and efficiency

- The application of packaging hot melt adhesive in the food industry: ensuring food safety and improving production efficiency

- Filter hot melt adhesive: reliable guarantee for the filtration system

- A new option for fixing Electronic wiring harness terminals: How does hot melt Adhesive Ensure stable connections and efficient production

13802979115

13802979115

2024-11-13

2024-11-13