- 【 Breaking News 】 Chairman Liao Yongping has been honored as the third president of the Guangdong Hunan Linxiang Chamber of Commerce

- Innovation in Bonding in Luggage Production: How does Hot Melt Adhesive Reshape Durability and Production Efficiency

- A new option for fixing Electronic wiring harness terminals: How does hot melt Adhesive Ensure stable connections and efficient production

- New Trends in Shoe material Bonding: How Can Hot melt Adhesive Sticks Enhance Efficiency and empower the Shoe-making industry

- Say goodbye to slow drying and glue overflow! Manual bonding of special hot melt adhesive rods ensures fast and stable production

- Innovating the bonding process of handbags: Hot melt adhesive is a powerful tool to reshape packaging quality and efficiency

- Hot melt adhesive sticks for car dent repair: Revolutionizing traditional techniques, reshaping repair efficiency and quality

- Odorless and no drawing! Exclusive hot melt adhesive sticks for export, unlocking a new experience of efficient bonding

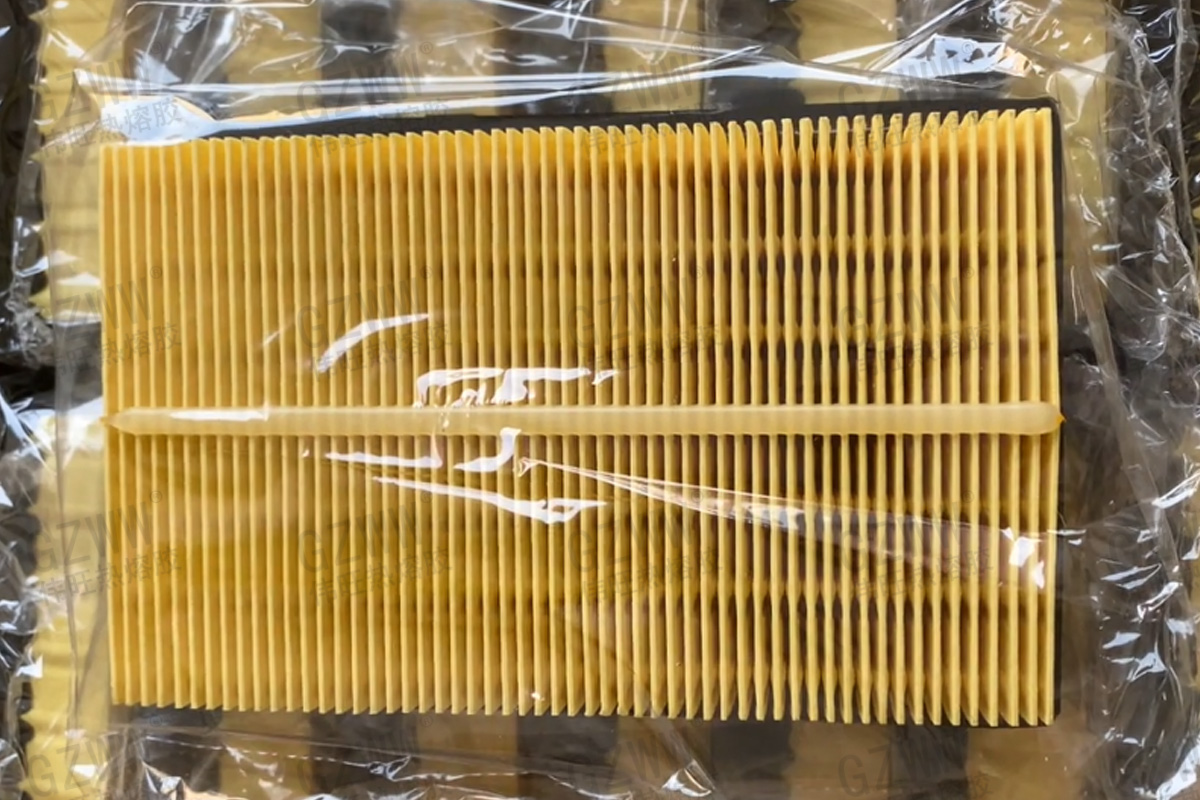

- How does hot melt adhesive empower cost reduction and efficiency improvement in the production of air filter elements

- New EPE pearl cotton bonding solution: Hot melt adhesive particles solve the bonding problems of multi-layer composites and special-shaped materials

In the field of filter element manufacturing, hot melt adhesive, as an efficient and environmentally friendly adhesive, is gradually becoming the first choice for filter element polyline bonding. With its unique advantages and a wide range of application areas, hot melt adhesive is bringing revolutionary changes to the filter manufacturing industry and promoting the continuous innovation and development of the entire industry.

First, the excellent advantages of hot melt adhesive

High efficiency curing: hot melt adhesive quickly becomes liquid after heating, can quickly fit the filter material and cure, greatly shortening the production cycle, improve production efficiency.

High strength bonding: Hot melt adhesive has excellent bonding performance, which can ensure the tight combination between the filter material, effectively prevent air or liquid leakage, and improve the filtration efficiency and service life of the filter.

Environmental protection and safety: hot melt adhesive will not release harmful gases during the curing process, which is harmless to the human body and the environment, and meets the requirements of modern industrial production for environmental protection.

Fine control: The spraying equipment of hot melt adhesive can achieve accurate glue quantity control and glue line positioning to ensure the fine degree and accuracy of the filter element line bonding.

Second, the specific application of hot melt adhesive in the filter core line bonding

In the process of filter element manufacturing, hot melt adhesive is widely used in the adhesion of filter paper, filter membrane and filter frame. Through the bonding effect of hot melt adhesive, the filter paper of the filter element can maintain a stable structure, and the filter membrane and the filter frame can be closely combined to form a complete filtration system. At the same time, the hot melt adhesive can also ensure the sealing performance of the filter element and prevent the leakage of air or liquid from the gap, thereby improving the filtration efficiency and service life of the filter element.

Third, hot melt adhesive to promote the development of the industry

The successful application of hot melt adhesive in the filter line bonding not only improves the production efficiency and product quality of the filter, but also promotes the innovation and development of the filter manufacturing industry. At the same time, the environmental protection characteristics of hot melt adhesive also meet the requirements of modern industrial production for green production, which helps the filter manufacturing industry to achieve sustainable development.

In the future, with the continuous innovation of hot melt adhesive technology and the continuous expansion of application fields, the application of hot melt adhesive in the filter element manufacturing industry will be more extensive and in-depth. We will continue to explore new applications and new areas of hot melt adhesives to bring more innovation and opportunities to the filter element manufacturing industry.

- Hot melt adhesive: Home versatile adhesive, making life closer

- What surprises can hot melt glue sticks bring?

- Can hot melt adhesive be used for mattress bonding?

- Is it really so good to bond pearl cotton with hot melt adhesive particles?

- How can I use a hot melt glue stick for everyday speakers?

- Is the use of hot melt adhesive in car interiors more beneficial than harmful or harmful than beneficial? It has become a topic of great concern.

13802979115

13802979115

2024-10-29

2024-10-29